Clay dry construction panel for solid clay construction

Life Cycle Transition

About the Product

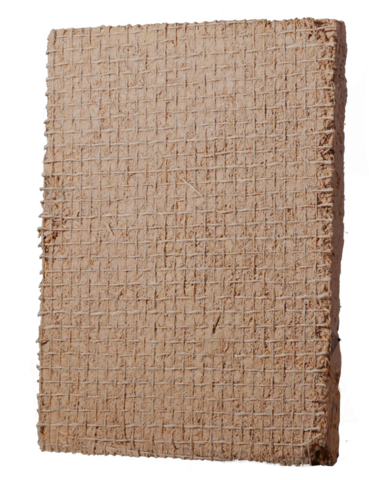

Clay drywall panels consist of building clay, clay, perlite, reed fabric, hemp and jute fabric. As a rule, the boards are screwed to a wooden or metal stud construction. The butt and bearing joints are sealed with a fabric and grouted with clay filler. After drying, the board is moistened, roughened with a nail board and can then be plastered with a clay fine plaster mortar.

The raw density is approx. 700 kg/m3 with a thermal conductivity of 0.13 W/(mK).

The clay building board LEMIX© by Hart Keramik AG is a prefabricated building board consisting of building clay, clay, wood fibres, starch and jute fabric laid only on the back. The most energy-intensive operation in the manufacturing process is industrial drying. With an apparent density of about 1450 kg/m3, it is an element of solid clay construction. The company Hart Keramik offers the boards in the format of 62.5 x 125 cm with thicknesses of 16 or 22 mm (23 or 32 kg/m²).

The clay building boards are used as dry plaster boards in interior construction. For this purpose, they are first screwed together, the joints are joined with jute tape and clay mortar and finally plastered over the entire surface. The clay dry plasterboard can regulate moisture in the interior and has a high thermal conductivity (0.35 W/mK).

If the unplastered clay building board is screwed down, it can be reused. Since it consists entirely of natural building materials, it can be returned to the biological cycle.

Manufacturer: Hart Keramik AG