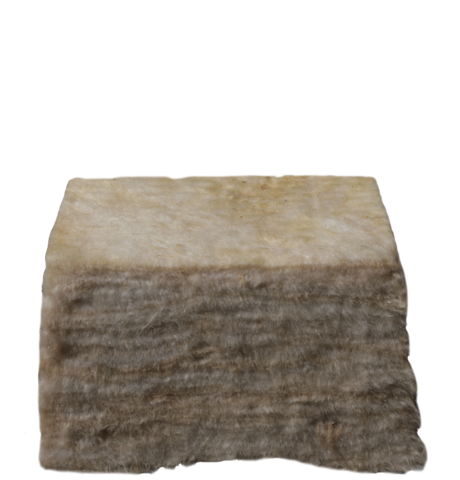

mineral wool insulation

Ecological Data per mass per volume

| Subject | Value | Unit |

|---|---|---|

| Primary Energy, non-renewable | 17.7 | MJ/kg |

| Primary Energy, non-renewable | 819.2 | MJ/m³ |

| Global Warming Potential | 1.5 | kg CO2-eq/kg |

| Global Warming Potential | 71.6 | kg CO2-eq/m³ |

(show values per volume) (show values per mass)

Life Cycle Transition

About the Product

For the production of mineral wool, mineral raw materials, quartz sand, lime, soda, iron ore and waste glass are used. In the case of glass wool, the proportion can be up to 80%. The components are brought together, spun by heat and shaped by binding agents.

The mineral wool insulation Ursa Pureone consists of artificial mineral fibres, which are mainly obtained from waste glass (50–70%). A water-based acrylic binder ensures that the fibres are cross-linked.

Mineral wool insulation, like the Ursa Pureone finds application as insulation of interior walls, interior insulation of walls, ceilings and roofs, suspended ceilings, as well as in wood frames and wood panel construction and has good heat and sound insulation properties.

Mineral wool insulation materials are not reusable in unchanged form for the same insulation application. In unchanged form they can also be reused for other insulation applications. For example, mineral wool insulating materials can be reused as so-called ”stuffing wool“. Mineral wool insulating materials can be returned to the manufacturing process (material recycling) if they are of the same type. Crushed mineral wool can be used as an additive for the production of fibre cement slabs and roof tiles or bricks”. (From ENVIRONMENTAL PRODUCT DECLARATION according to ISO 14025 and EN 15804 PureOne by URSA, Institut Bauen und Umwelt, 2012–2018)

Manufacturer: URSA Deutschland GmbH