glass ceramic from recycled glass

Ecological Data per mass per volume

| Subject | Value | Unit |

|---|---|---|

| Primary Energy, non-renewable | 0.4 | MJ/kg |

| Primary Energy, non-renewable | 966.0 | MJ/m³ |

| Global Warming Potential | 0.0 | kg CO2-eq/kg |

| Global Warming Potential | 76.3 | kg CO2-eq/m³ |

(show values per volume) (show values per mass)

Life Cycle Transition

About the Product

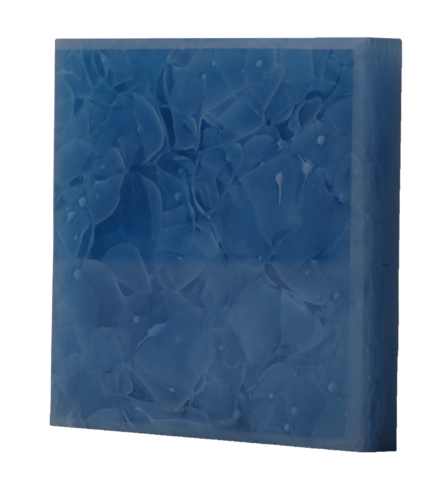

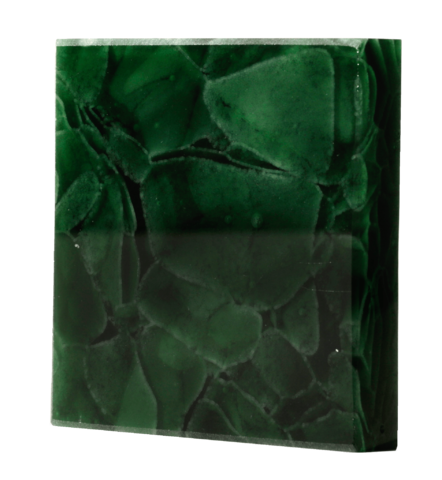

In the glass industry, approximately 5% of waste is generated by overproduction or production failures. The glass waste can be used for the production of glass ceramics. It is first crushed and sintered. After cooling, the plates are calibrated, adapted to the desired dimensions and polished as required.

The finished glass-ceramic plates are translucent and the manufacturing process creates unique structures. The field of application is very diverse: Besides the use in furniture construction, the glass ceramic panels can also be employed for interior fittings or as façade material. If glass ceramic only contains recycled glass and no additives, it can be completely returned to the material cycle after use.

Magma glass ceramics consists of pure waste glass. The product is manufactured under environmentally friendly conditions and without the addition of binders. According to the manufacturer, solar energy and pre-used water are mainly utilized in the production process. The product has a Cradle to Cradle Gold certification.

Manufacturer: MAGNA