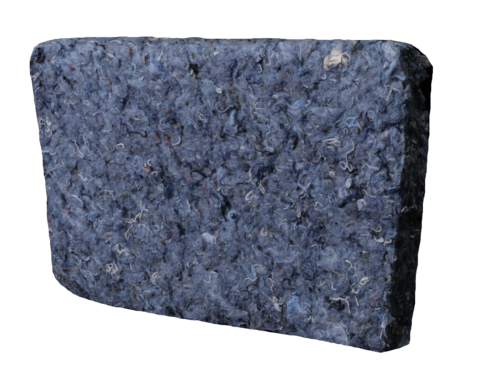

used denim insulation

Life Cycle Transition

About the Product

Denim is made from dyed cotton threads and categorised as waste when the textile is no longer in use. The high consumption of fertilisers and water as well as the use of harmful chemicals in the production process of the denim fabric are regarded critically.

The used fabrics are sorted manually and then mechanically torn and shredded. The shredded materials can be used directly as loose blow-in insulation or mechanically compacted and pressed into webs in the subsequent process. About three pairs of jeans are used per square metre of insulation (100 mm thick). Manual sorting of garments and fabric remnants reduces energy consumption in the manufacturing process.

Denim insulation is used as thermal insulation or acoustic insulation in interior walls, ceilings and floors. After use, the insulation can be recycled. The blow-in insulation can be sucked off and the sheets can be shredded again.

The British company Inno-Therm® manufactures heat and sound insulation according to EU and UK standards. For the product Metisse® insulation, 85% used denim and 15% polymer binders (PES) are used as insulating material. According to the company, 70% less energy is required for production than for mineral wool. The insulation is available in fabric panels with a density of 20-25 kg/m3 or as blow-in insulation.

Manufacturer: Inno-Therm®